Fashion and promotional print on textile is our specialty.

So if you need especially demanding forms of print on textile,

we are the right address.

Print on textile is a printing type that always demands high precision, innovative approach and the most advanced technologies for special effects.

We put our clients’ particular requests first, each of our solution is custom-made and each our item passes strict quality control.

This is why our T-shirts are even internationally recognized as top-quality and innovative products.

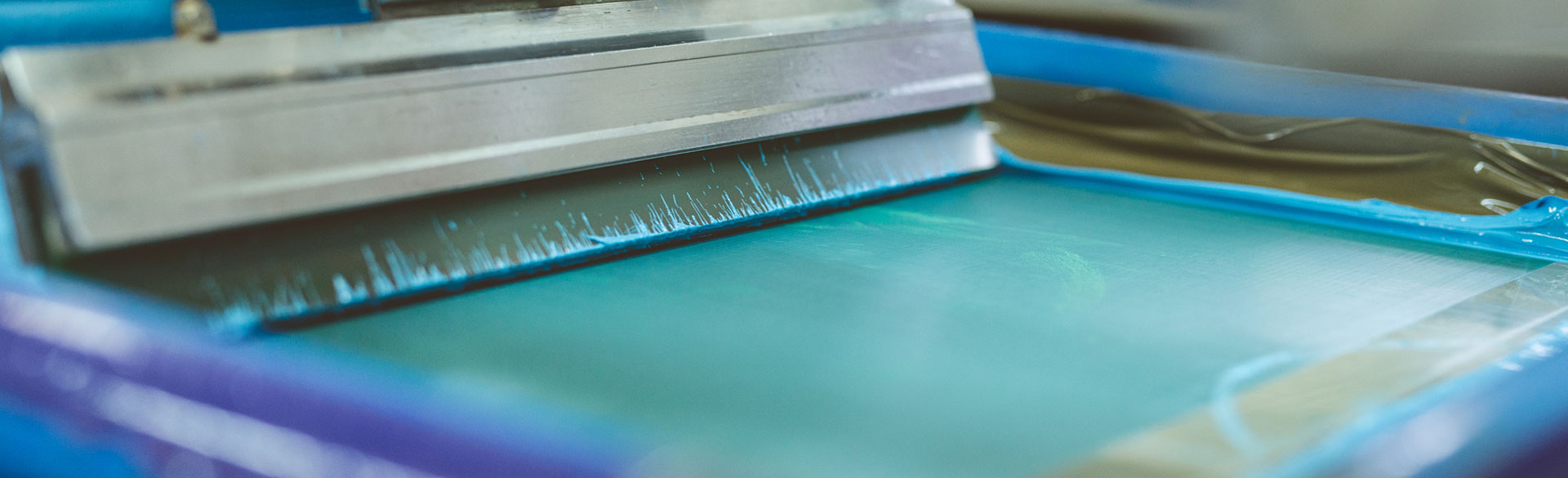

Screen printing

This is technology we prefer and suggest in most of the cases.

Screen is made by colour pushed through the mesh opening, except on parts which are blocked by emulsion (photosensitive chemical).

Wet colour extruded comes in direct contact with a textile base, which guarantees excellent adhesion, and by that quality and durable print.

There is no faster, cheaper or more reliable option than direct screen printing, when it comes to larger quantity of goods.

We will always recommend screen printing technology in this case.

Also, rich variety of special prints is definitely one of the main advantages of screen printing technology.

TECHNOLOGY ADVANTAGES:

– Cost-effective print per piece (when 50 pcs+)

– Top fastness and durability

– Top colour saturation

– Various types of textile bases

– Numerous possibilities of special effects

Excellent colour fastness

Beads in 2 sizes, transparent or coloured. They make a nice esthetic effect addition to print.

In 6 colours. Metalic colours with excellent fastness.

Puffed emboss effect

3-D print.

Phosphorus light colours.

High shine varnish for special effects

Colours that change its shade when exposed to UV or sun light.

Crystalline and yellow sparkle. Transparent glitters.

For stretchy materials and clothes, e.g. bathing suits, lycra, spandex and mixtures of cotton and elastine.

Raised fluffy print

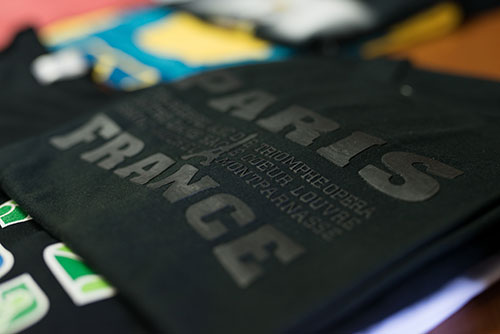

Mildly embossed suede imitation.

Print with premium softness on black material, made with ectching method, and only for shirts coloured with reactive colour.

Special colour that is visible under special UV lights, e.g. in disco clubs.

Special colour that is visible under special UV lights, e.g. in disco clubs.

On black and white.

DTG print

Direct to garment print. Technology of digital direct print on cotton base.

This technology is recommended for cotton base, for small circulations up to 50 pcs, and for products where colour saturation, sharpness or fastness are not crucial to fulfill a screen print level.

TECHNOLOGY ADVANTAGES:

– Print of top quality photographies

– Number of colours doesn’t effect the price, only size of the print

– Possibility of printing on only 1 single item

– Softness of a print

– Short preparation phase and quick production start

Transfer print

Technology that is best effective for small textile bases, and products that often go in reprint (e.g. stickers, caps, numbers for sports shirts etc.), because there is no additional print preparations and costs.

This technology is recommended for:

– small runs

– when cad-cut decal is not involved in process

– when print doesn’t have to be same material as base

Production process

PRE-PRESS

Production process begins with a print preparation for which we use 2 PCs, with professional software and calibrated monitors for highly precise reproduction.

We do films in-house, and on film exclusively, not on tracing paper, for more quality and precision in colour reproduction.

DESIGN MEETS COLOURS

We use colours from our in-house colour charts, or we mix them by pantone, to achieve the best reproduction precision.

Colours are being mixed professionally, with recipes, colour mixer and scale.

Colour goes to pre-press check, just to get sure if tone is 100% accurate to colour shade.

SCREEN EXPOSING

Screen exposing on professional metal halide frame with vacuum, for quality filming all the details.

Professional washing and checking the screen with backlight for quality control of developing. Mistakes if any, are corrected this very moment so they are not visible on material.

PRINTING

Depending on number of colours, we print on adequate equipment, manual or automatic, depends on a circulation.

We print with premium American colours Union Ink, in 905 cases with plastisoles.

We make proof prints on our own materials to double-check all parameters, and only after that, we begin with printing on your goods.

We constantly follow print control, colour clarity and sharpness, we track for mesh leakage if any, we check print height, print position, timing of colour drying (we use professional dryers with time delay and time control, to maintain a constant level of colour drying – especially in print on dark materials, because we print a white colour base to achieve a quality colour no matter the base colour.

This is why it’s very important to dry a white colour exactly the time that is needed to achieve a maximal adhesion and fastness, which we can guarantee if instructions are accurately followed.

For example, black shirts shouldn’t be washed on 90C, foils and materials with special effects on over 30-40C. Although they are resistant to higher temperatures, colour would lose its stability over time and after number of washings.)